Casting is a process of molding metal into different shapes and sizes to create metal parts. It is one of the oldest methods of forming metal parts, and it has undergone significant advancements. The two most common types of casting are gravity casting and die casting. Both of these techniques have their advantages and disadvantages, and understanding them can help you make an informed decision when choosing between the two.

Gravity Casting

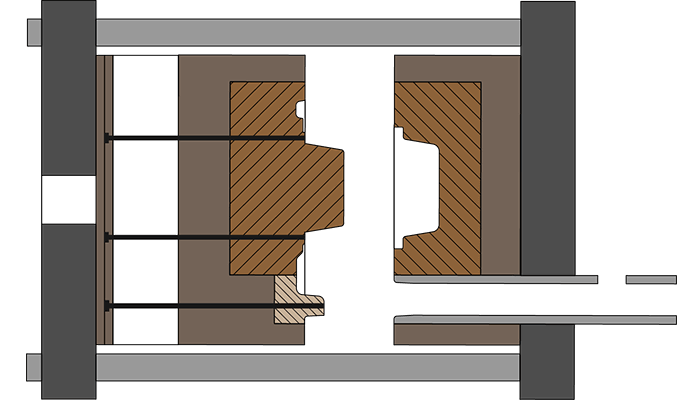

In gravity casting, gravity is used to ensure that all the parts of the mold are filled by the melted metal. This technique is simple and straightforward, as all you need is a gating system, a mold, and melted aluminum or zinc. After the liquid metal is poured into the mold, it is left to cool, resulting in the desired shape or design.

One of the advantages of gravity casting is that it can produce as many as 100 parts in a day. However, this method primarily relies on gravity, which means that it is not guaranteed that the metal will seep into all parts of the mold. An inferior plate or part may result, which is not ideal for industries that require precise parts.

Die Casting

On the other hand, die casting uses high pressure to pump the melted aluminum into cold chamber molds. This technique ensures an accurate model of the planned metal fixture. Additionally, the high pressure guarantees a smooth and shiny surface for the aluminum parts. Die casting can manufacture from 500 to thousands of parts in a day, making it more productive than gravity casting.

DT-TotalSolutions, a high-technology company, specializes in providing one-stop total-solutions service by carrying your concept or idea into automation production and assembly. It helps you get the final products you precisely want through its efficient and effective production methods. DT-TotalSolutions is capable of both gravity casting and die casting, allowing them to create intricate designs of high-quality and precision.

Getting a Price for Aluminum Die Casting Parts or Die Casting Tooling

If you require aluminum die casting parts, DT-TotalSolutions offers competitive pricing. To get a price for aluminum die casting parts or die casting tooling, call toll-free 800-524-8083. DT-TotalSolutions diligently works to provide customers with quality products and services at the best possible prices.

Conclusion

Casting is a vital process in creating metal parts of various shapes and sizes for different industries. When choosing between gravity casting and die casting, it is essential to consider the accuracy and precision of the required parts. Gravity casting can produce up to 100 parts, while die casting can make from 500 to thousands of parts in a day, making die casting more productive. Additionally, DT-TotalSolutions offers one-stop solutions for your automation production and assembly needs, making them an ideal partner for creating quality and efficient metal parts.