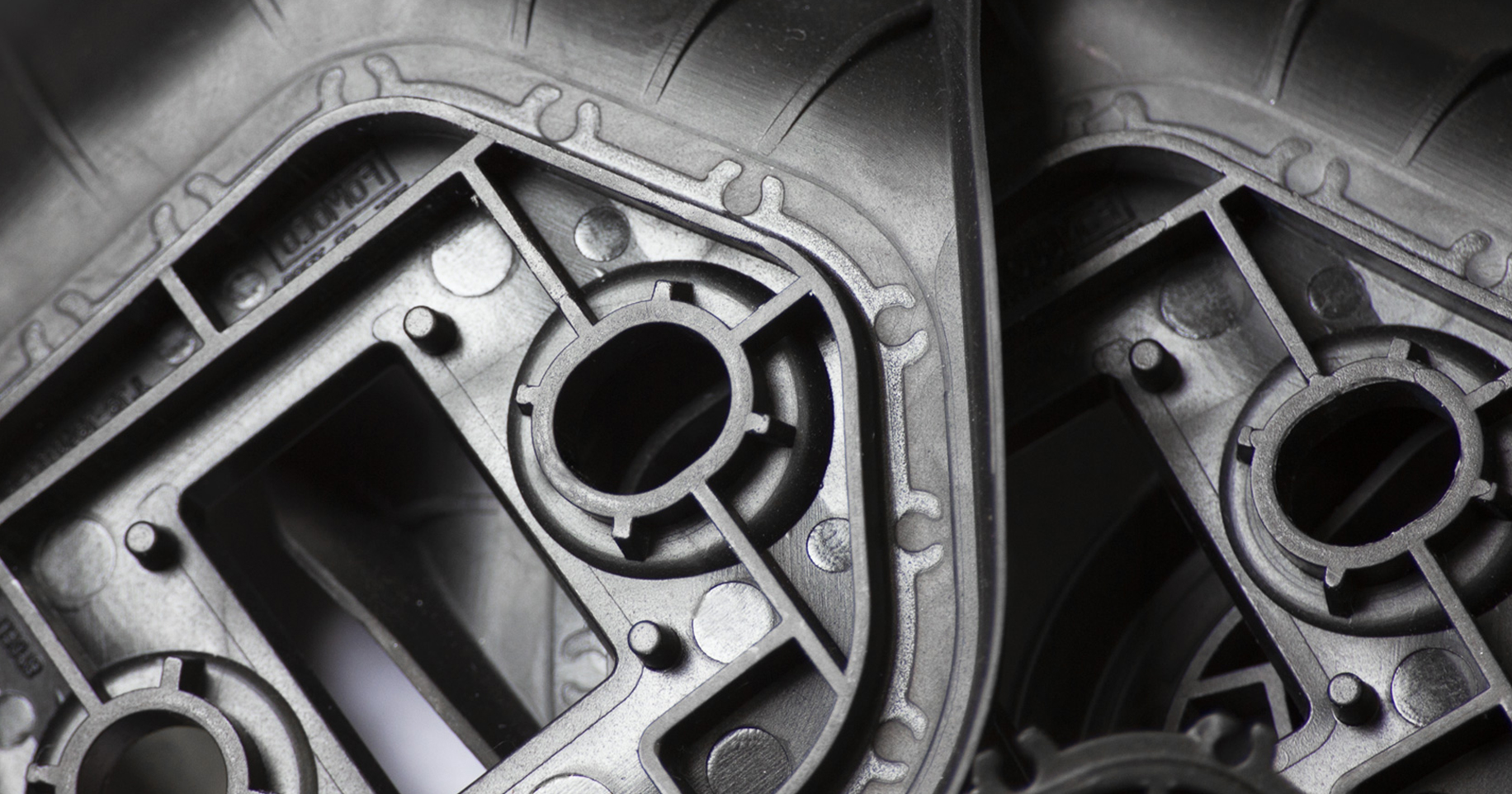

What is Plastic Injection Mould Tooling?

Plastic injection molding is a process used to create a range of plastic products from toys to automotive parts. It involves melting plastic pellets and injecting the molten plastic into a mold tool, which is designed to produce the desired shape. The mold tool is made up of two halves, the cavity and the core, which form the part's shape when closed. Once the plastic has cooled and hardened, the mold is opened, and the finished part is ejected.

Why is Tooling Services Important for Plastic Injection Molding?

Tooling services are essential for plastic injection molding because they ensure that the mold tool is in good condition, which affects the quality of the final product. By properly maintaining the mold tool, companies can achieve consistent part quality and reduce manufacturing downtime. Here are some of the benefits of having a well-maintained tool:

1. Improved Efficiency:

A well-maintained mold tool can reduce manufacturing downtime, increase productivity, and improve overall efficiency. If the mold tool is not in good condition, it can cause manufacturing delays, product defects, and even safety hazards.

2. Consistent Part Quality:

A well-maintained mold tool can produce consistent and high-quality parts. By ensuring that the tool is in good condition and operating correctly, companies can achieve the desired part quality every time. This is important for meeting customer expectations and maintaining a good reputation.

3. Cost-Effective:

Having a well-maintained mold tool can also be cost-effective in the long run. By reducing downtime and improving productivity, companies can increase their output and reduce manufacturing costs per unit.

What are the Different Types of Tooling Services?

There are many different types of tooling services available for plastic injection molding. Here are some of the most common:

1. Preventative Maintenance:

Preventative maintenance is a regular service that involves inspecting and servicing the mold tool to prevent issues before they occur. This includes cleaning, lubricating, tightening, and adjusting the tool to ensure it is in good condition.

2. Corrective Maintenance:

Corrective maintenance involves repairing the mold tool when issues arise, such as cracks, wear, or damage. This includes replacing parts, correcting alignment issues, and addressing any other problems that may affect the quality of the final product.

3. Upgrades and Refurbishments:

Upgrades and refurbishments involve improving the mold tool's design or performance. This includes adding new features, updating technology, or repairing worn parts to improve overall efficiency and productivity.

Conclusion:

Tooling services are a vital aspect of plastic injection molding, and they play a crucial role in achieving efficiency and part quality. By properly maintaining the mold tool, companies can reduce manufacturing downtime, increase productivity, and improve the quality of their products. To learn more about tooling services, contact (remove brand name) or visit our website.